Part 1: Axe Handle Selection

Replacing an axe handle (a.k.a. haft, helve) can be very frustrating for axe users and enthusiasts. However, it is a skill that can really come in handy! When you think about it, an axe is a hunk of steel driven onto a wooden stick. Wood is a natural material, and even seemingly “perfect” handles may be flawed in some way or another. I say this not to discourage, but to remind users that sometimes handles will not hold up. Whether due to general use, lack of care, or even accidents such as overstrikes, at some point you will have to get a new haft for your axe!

In this guide, I will discuss how to select the proper handle for your axe head. Whether your current axe handle just broke, or you found a vintage axe head at the flea market, selecting the proper haft is the first step. This may be common knowledge or seem trivial, but my hope is that it will help both beginners and veterans of the “axe game.” Later on, I will guide you through the steps of replacing your newly selected handle.

The steps of handle selection will all depend on the current state of your axe. Is your axe handle broken? If so, does any wood still remain in the eye of the head? If any wood remains, you will need to remove it in order to measure the eye.

Step 1: Remove the old handle (if applicable)

Step 1: Remove the old handle (if applicable)

Tools that I use include:

- Vise with a set of non-marring vise jaws

- Saw (coping saw preferred)

- Hammer

- Drift or punch (either metal or wood)

- Gloves

- Safety glasses

Put the axe head in the vise, and use your saw to cut off the handle as close to the axe head as possible. Be sure not to saw into the metal of the head! Next, use your drift or punch to drive out the wood. Drive the wood out through the top of eye, or in the same direction that the handle was inserted. Please note: your haft may have been hung incorrectly, where the top of the handle protrudes out the bottom of the eye. Just make sure to distinguish the top from the bottom before selecting your new haft, as explained in Step 2. If the handle is being stubborn and won’t come out, drill a few holes in the bottom of the handle, opposite the wedge, and try to drive the wood out again.

Step 2: Measure the eye of the axe

For this step, I find that a digital micrometer works best. If you don’t have one handy, then a ruler will do just fine. We need to determine which is the top of the eye, and which is the bottom. Measure the length and width of both sides at the widest point, and the smallest side should be the bottom of the eye. These measurements should be close, but knowing which side is which will make all the difference.

Units of measurement – this will depend on the brand of axe you are using when buying your new handle. For most of the handles that I’ve ever ordered, the eye size is measured in inches. For this particular project, I ordered a new Hults Bruk handle for my vintage Hults Bruk Montreal pattern hatchet head. Hults Bruk handles are based on eye sizes measured in millimeters, so the eye should be measured with this in mind.

Step 3: Determine which handle to use, based on eye size and length.

Selecting a handle is definitely an art more than a science. Ultimately, it comes down to intended use and personal preference. Since I’m shorter (5’9”) I prefer shorter handles than someone taller. Also, think about the type of axe you have at hand: is it a small hatchet that will be used to split kindling, or a large axe intended for felling trees? The Hults Bruk hatchet head that I have, which is in need of a new handle, will be used for small work such as splitting kindling.

If ordering a handle, there are usually size guides on the company’s website. If you’re unsure, give the company a call and tell them what you have and the size of the eye. As a general rule, it is best to order a handle with dimensions slightly bigger than the eye of your axe head. Trimming a handle that’s slightly bigger will allow for a tighter fit.

Since I want to hang this hatchet using a new Hults Bruk haft, a little research had to be done beforehand. I found out that Hults Bruk axes should have one of three eye sizes, all measured in millimeters. They are: 42×15, 50×20, and 63×23.

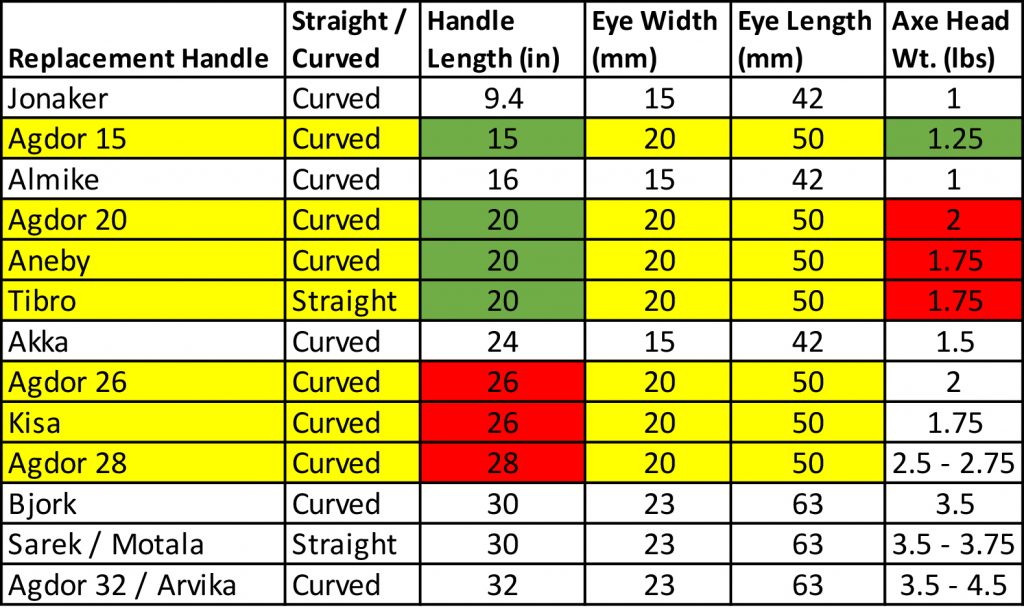

I created an Excel spreadsheet as a reference for my particular project. You don’t have to do this by any means; I only did this for a visual reference in explaining my thought process. The vintage Hults Bruk head that I have measured 48mm x 17mm. The closest eye dimensions would be 50×20, which is slightly larger than the eye of my axe (exactly what we want). This tells me that multiple Hults Bruk replacement handles will fit the eye of my axe, which are highlighted in yellow in the below chart.

As you can see, there are 7 different replacement handles that will fit into my axe head. However, there are a few things to note. First, the Tibro handle is a straight handle (rather than curved). Also, the Aneby and Salen/Gran handles are essentially the same handle, only difference being a slightly different palm swell, and printed/stamped logos.

With this in mind, we now move to the handle length and head weight combinations. These numbers came straight from the Hults Bruk website and catalog. In the “Handle Length” column, you’ll notice three handles marked in red. These are the three handles that I decided would not work for my particular hatchet head, as they are intended for larger felling axes.

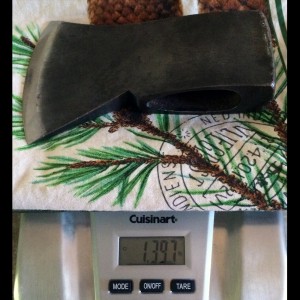

Now, we move over to the final column showing the axe head weights of each model. I weighed my hatchet head using our digital kitchen scale, and it showed a weight of 1.397 pounds. Based on weight alone, my axe head closely resembles the Tarnaby model, highlighted in green. I decided that this would be the handle to order for my hatchet head. Could I have ordered the Tibro model replacement handle (20” straight), and cut it to the desired length? Absolutely! However, my preference is a curved handle when splitting kindling, which will be the primary use of this hatchet. Would a 20” curved handle (Aneby, Salen/Gran models) also work? Yes it would, however the weight, length, and intended use are more conducive to the shorter 15” handle.

Remember; selecting a new haft is an art, but it doesn’t have to be a difficult task. Talk to other axe lovers and users about their preferences, and don’t be afraid to try something new. I hope this guide will help you along the way during your next axe project. Be sure to check out the second part of this series on how to install a new axe handle.

Continue to Part 2 – How to Replace Your Axe Handle – Handle Installation

Disclaimer: For Educational and Informational Purposes Only. Although care has been taken in preparing this information, Hults Bruk and Jared Allement are not responsible for any errors or omissions, and neither party accepts liability for any loss or damage.

Manufacturing defects are covered under product warranty. Damage from improper usage, or normal wear and tear, are not covered under any warranty. If you have a new HB axe that you believe is defective, please contact the retailer you purchase the axe from first.

HB uses top quality American hickory handles that with care should last for many years of use. Click here for information about ordering replacement handles online.